process

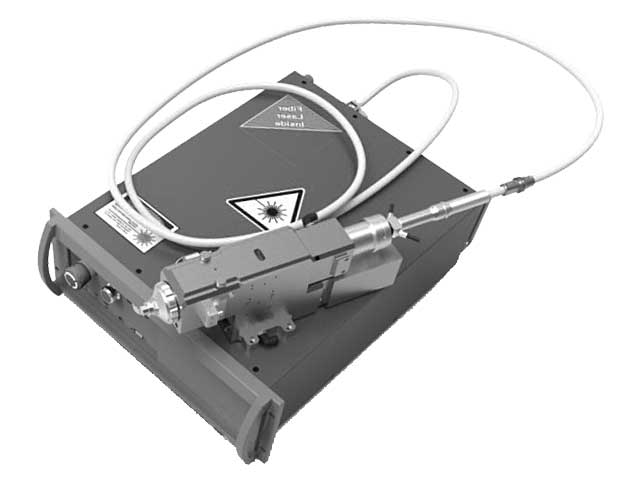

Laser

Cutting

Laser cutting machine is primarily used for industrial manufacturing applications. It can also be defined as a technology that uses a laser, to cut materials. This machine is uniquely designed for cutting various kinds of metals & non-metallic materials.

Cutting metallic & non-metallic materials is possible with the help of laser cutting machine. Some of the essential features of laser cutting machine are high processing speed, reliability, durability, flexibility, high accuracy, outstanding cut quality, high efficiency, excellent beam quality, longer service life and negligible maintenance.

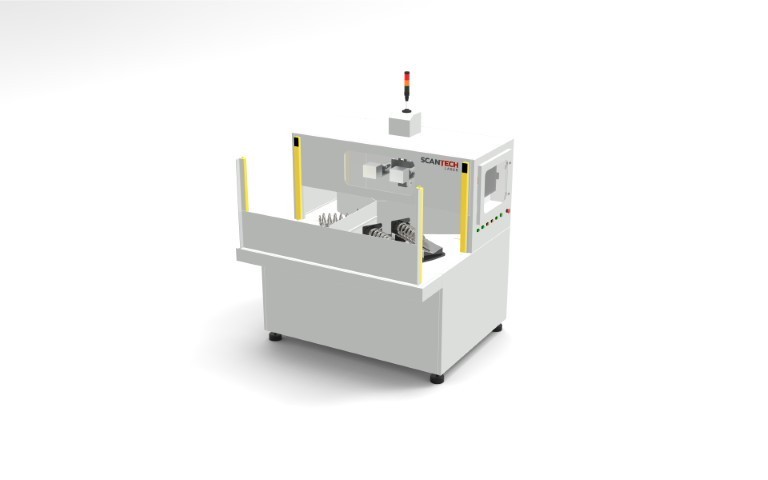

ProCut 1000

1000 series is Eco-friendly as supports the green technology and with enclosed working area.

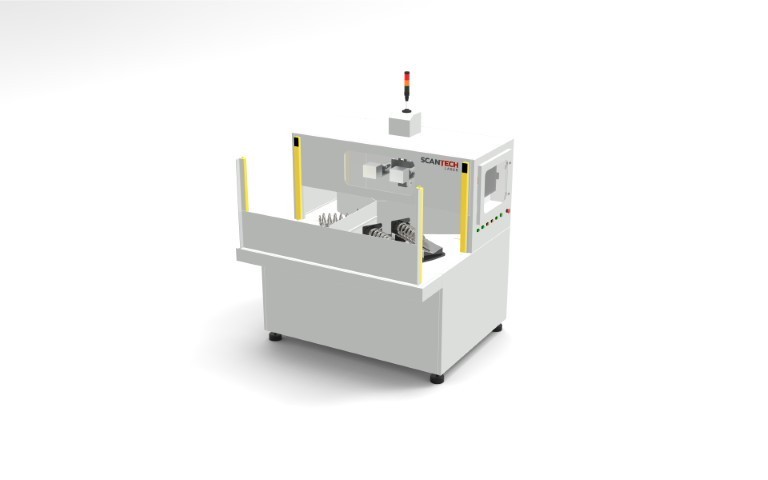

ProCut 2000

2000 series is Eco-friendly as supports the green technology and with enclosed working area.

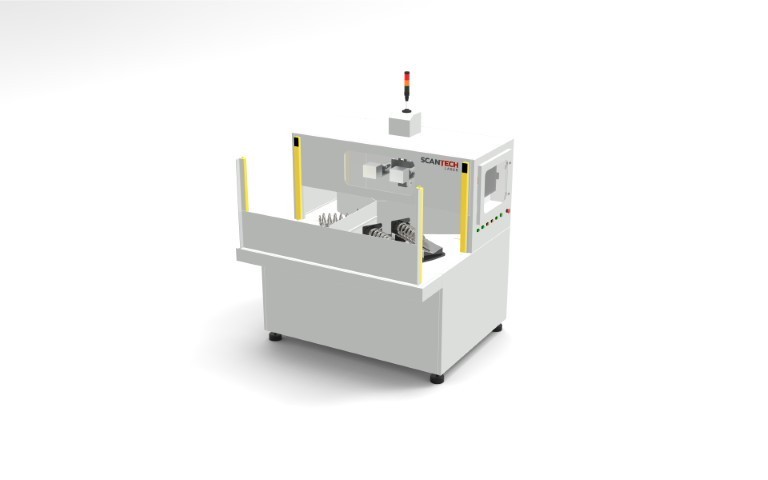

ProCut 3000

3000 series is fully customized as per the customer’s need, can work on any metal sheet i.e. formed, irregular etc.

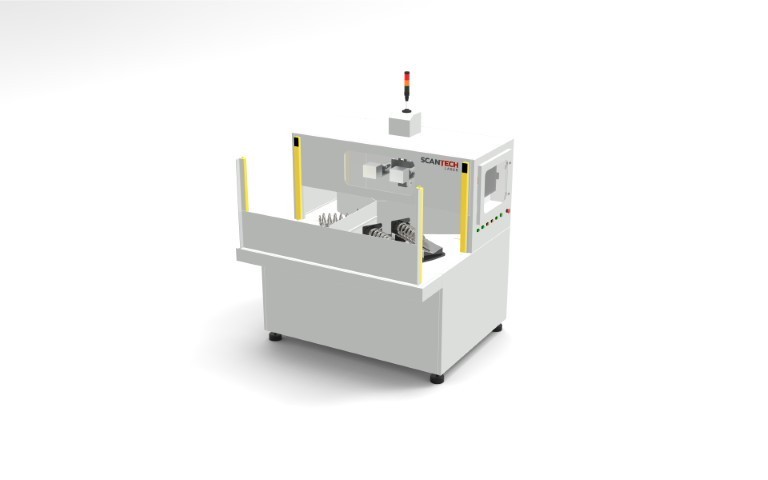

ProCut 4000

4000 series With robot does the work on any 3D work piece as per the requirements.

Comparison - Laser vs Alternate

Laser Cutting

Plasma Cutting

Waterjet Cutting

Wire Cutting

Advantages of Laser Cutting

Faster Cutting Speed

High density of energy focused with a small spot size making the material softer at very rapid speed which results in faster cutting.

High Accuracy

Smaller spot size helps to create smaller kerf width results in superior edge finish & better accuracy of ±0.1 mm

Lower Running Cost

High electrical efficiency & maximum material output, resulting in considerably lower running costs.

Low Maintenance

No moving mirrors in the light generating source, reducing maintenance, and operating costs.

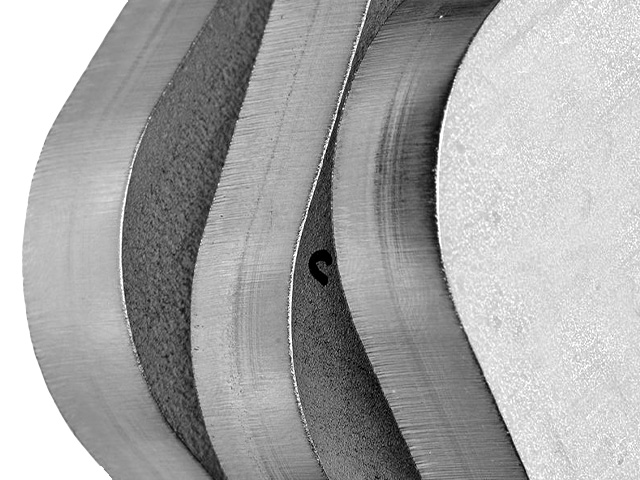

Materials that Laser Cuts

Related Solutions

Related Posts

5 Best Features of Robotic Laser Cutting Machines

Both laser technology and robot technology are processing rapidly, with robotic laser cutting machines becoming increasingly popular in the automobile industry. Due to its technolo

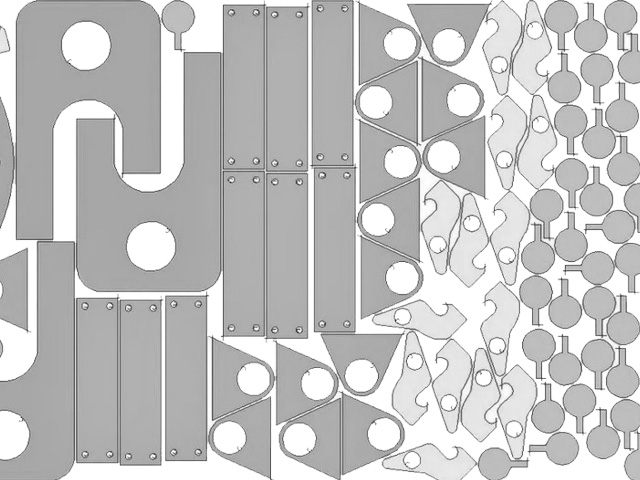

Uses Of Laser Cutting Machine For Architectural Models

Laser cutting machines are considered ideal for creating architectural models. There are many reasons why laser machines should be given precedence over other forms of the machine

How To Have A Fantastic Laser Cutting Machine With Minimal Spending

Suppliers and who support other industries with their production technology and precision equipment have several ways of providing their clients with just what they need. The top l

Learn How To Utilise 3D Laser Cutting Machine To The Fullest

Most people who possess laser cutting machine use it for either one or two specific purposes. These machines have a highly versatile nature and they can be used to produce [&hellip