process

Laser

Welding

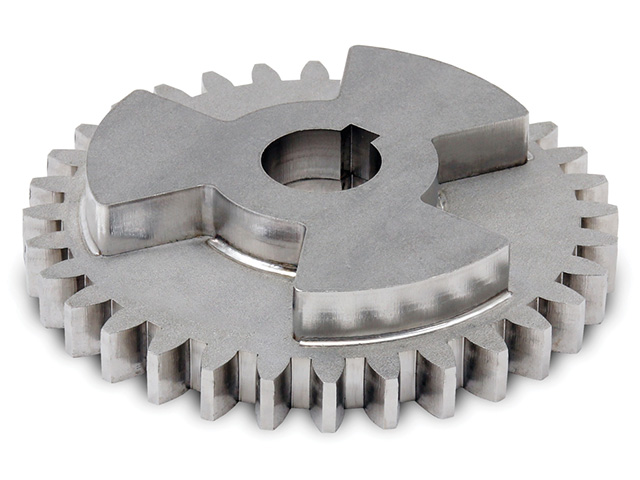

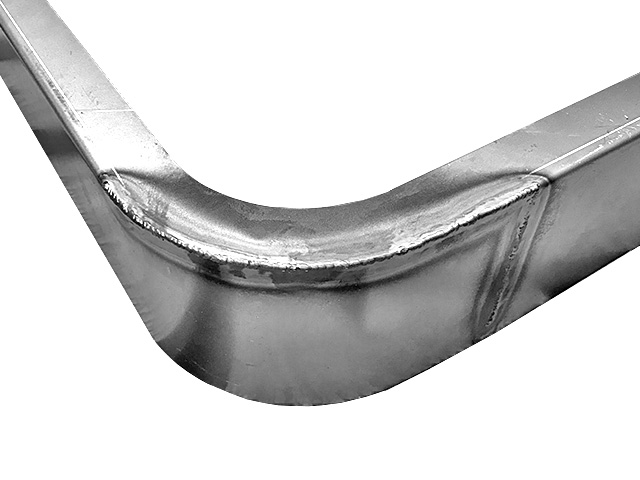

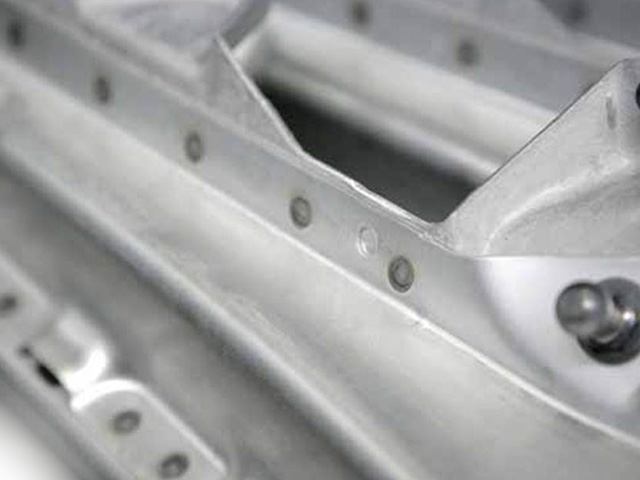

Laser Welding Technology is one of the most hopeful technologies in a diversified range of Industries from Aerospace to Jewelry Making. Laser welding is applicable for both metals as well as thermoplastics. There are several types of Laser Welding i.e. Butt Type Welding, Keyhole Welding, T-shape Welding, Lap Welding and many more. These are applied as per the application. During the Laser welding, a highly concentrated beam of Laser is used to focus on a tiny spot of the workpiece then the defined area absorbs the Light and becomes highly energetic. Laser transmits its heat energy through the narrow beam, melting only the localized specialized area. Due to much less total heat input than other welding methods processing parts cools very rapidly, minimum distortion and impact on metallurgical effects. Requirement of Maintenance of Laser Welding System is comparatively less and cost effective than others welding technology.

Our Products

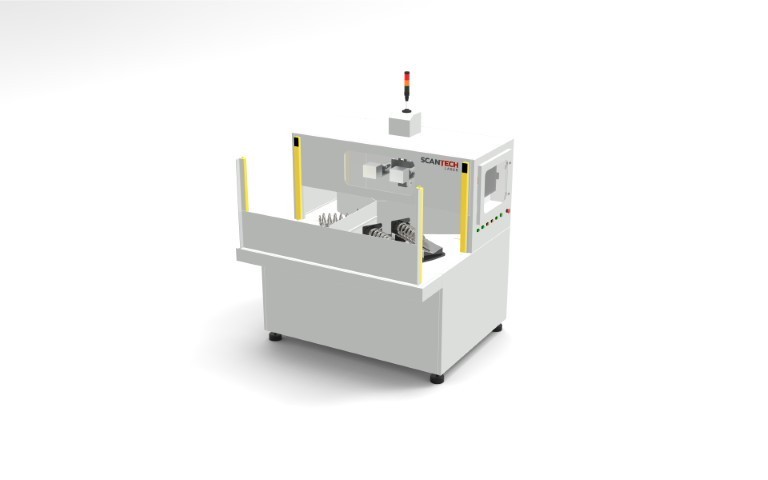

ProWeld 1000

1000 series is budget friendly as well as productive and significantly able to serve the purpose.

ProWeld 2000

2000 series is handheld and portable, suitable to weld giants or fixed components.

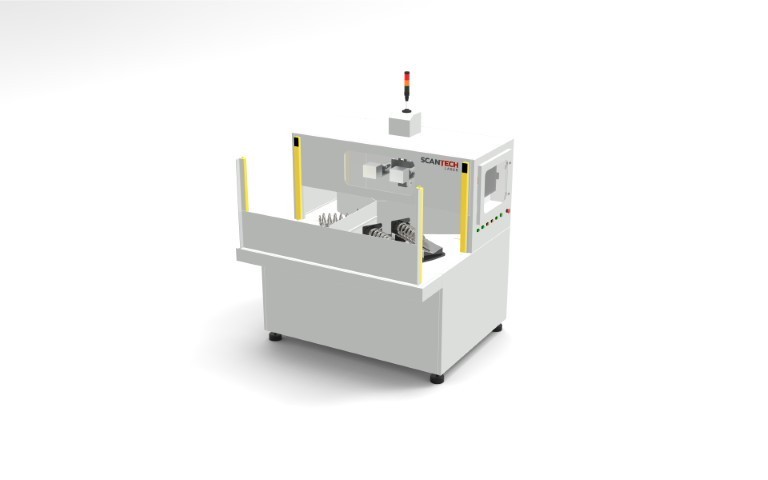

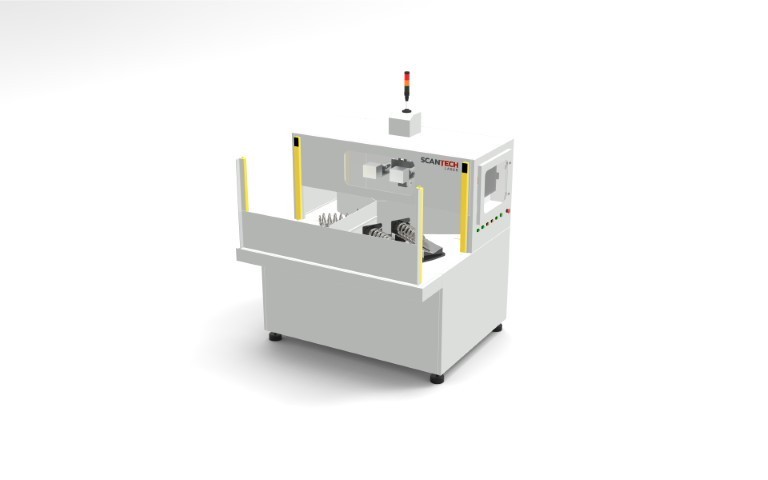

ProWeld 3000

3000 series is fully customized as per the customer’s need, can weld any shape of parts i.e., formed, irregular etc.

ProWeld 4000

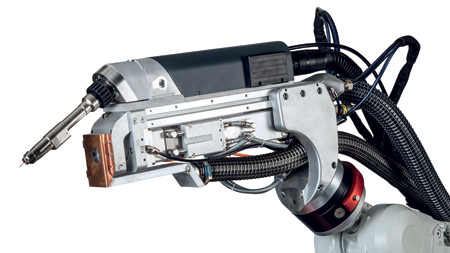

4000 series comes with robotic welding head, welds any 3D work piece as per the requirements similar metals as well as dissimilar.

Comparison - Laser vs Alternate

Laser Welding

ARC Welding

Resistance Welding

Electro Beam Welding

Advantages of Laser Welding

Low Heat Affected Zone

High Welding Strength

High Precision Welding

Complex Welding

Related Posts

Importance of Laser Welding – Battery Application

The market for all batteries continues to grow as the global demand for wireless and environmentally safe electronics increases. This includes electronic devices such as mobile pho

6 Benefits of Hybrid Laser Welding

Hybrid laser welding is a process in which laser welding and any other welding process are combined into a single process. Another welding process can be a process such as [&hellip

5 Uses of CNC Laser Welding Machine

To start with CNC, it stands for Computer numerical control. It can be described as the automation of machine tools with the help of machines with the feature of executing [&hellip

What is the Laser Welding Process?

Laser welding process is used to join different pieces of metal together with the help of the laser. The process of welding through laser can be primarily divided into two [&hellip