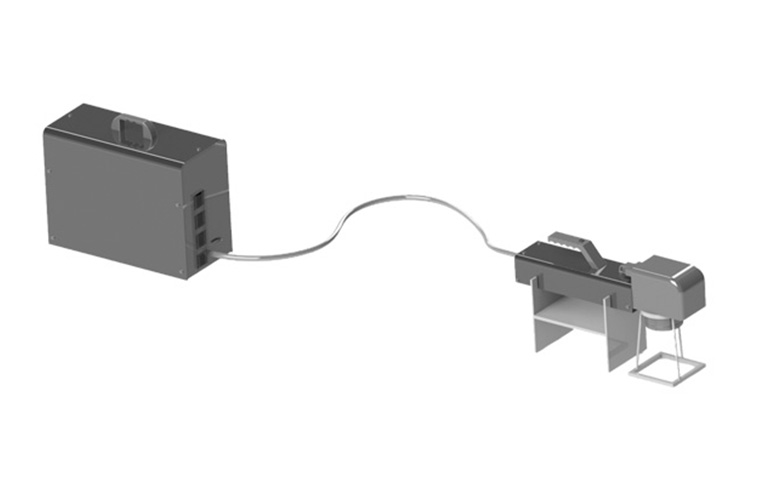

ProMark 2000

High performance industrial laser marking machine for challenging components & environment.

All images & specifications mentioned are for reference purpose and are subject to change without notice.

Related Posts

Portable Laser Marking Machines – Best for Automobile Industry

Laser marking technology is being used in a number of ways by people every day for decades. From deep, permanent serial number marks to beautiful designs laser technology can make

Why Laser Engraving Is Better Than Traditional Engraving

Going to make new jewelry and want it to be engraved? The first question the jeweler will ask you is, “Do you want traditional engraving or laser engraving?” and the […]

Know The Difference Between Laser Marking and Laser Engraving

The laser marking and engraving devices are being integrated into various industries due to their ability to undertake a number of different tasks. Another reason for the rise in t

5 Reason Why To Use Laser Hallmarking On Jewelry

Many people are beginning to take up the hobby of creating customized jewelry. Such customized jewelry is a nice option for a gift since the person can engrave any customized [&hel